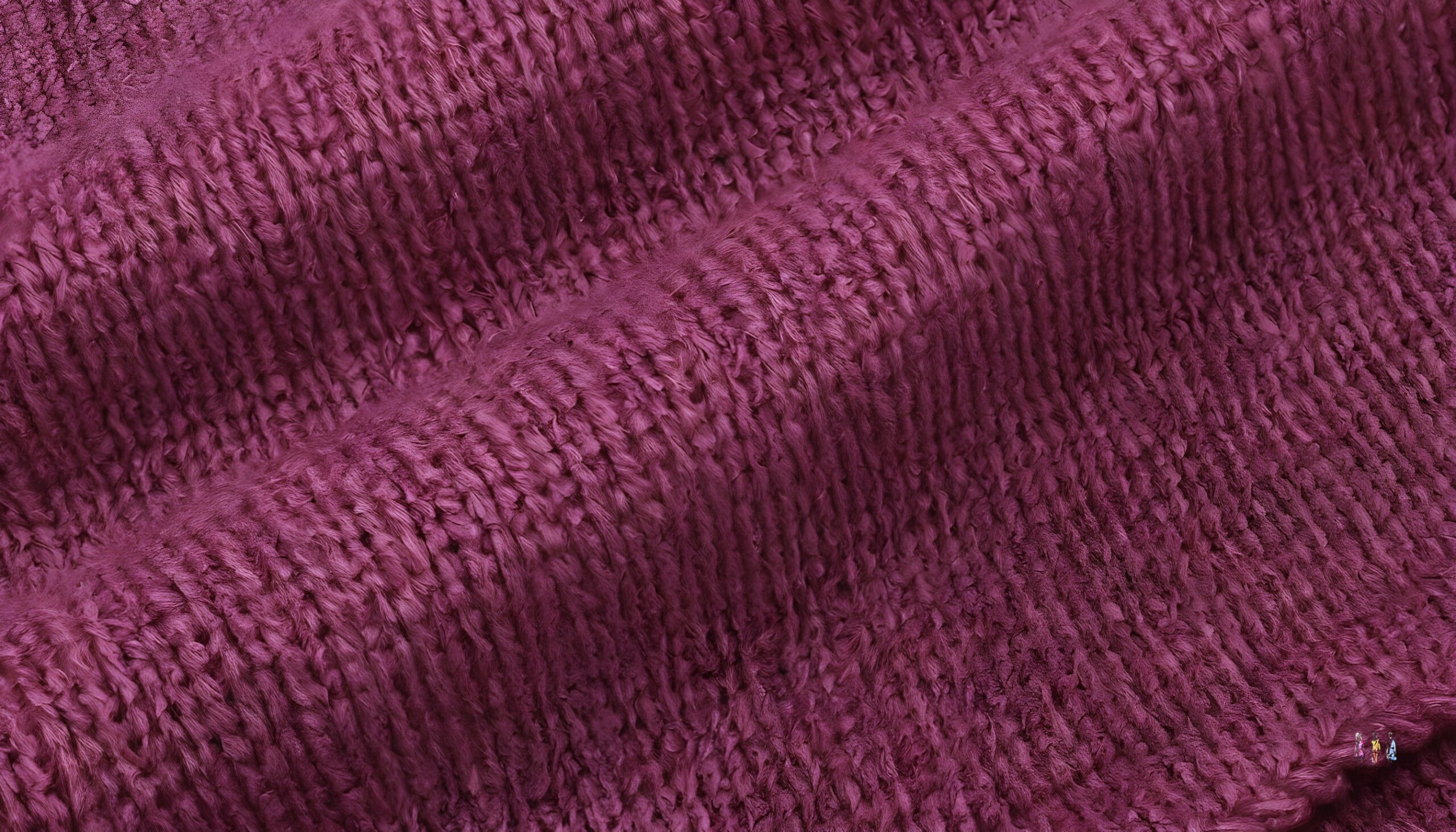

Rib knit is a type of fabric characterized by its distinctive vertical ridges or “ribs.” It is a textured knit fabric that features raised parallel lines or cords on both the face and the back of the fabric. These raised lines are created by alternating raised and lowered stitches, producing a stretchy and textured surface.

Here are key features and characteristics of rib knit fabric:

Structure:

Rib knit fabric is constructed using a specific knitting technique where vertical raised lines (ribs) alternate with recessed lines.

- Knitting Technique:

- Rib knit is created using a knitting technique where needles interlock yarns to form a series of loops.

- In rib knitting, the needles create vertical columns of raised stitches (knit stitches) that alternate with recessed stitches (purl stitches).

- Raised Ribs:

- The raised ribs in rib knit fabric are formed by knit stitches. These stitches are pulled to the front of the fabric, creating a textured, raised line.

- The raised ribs give the fabric its characteristic pattern and contribute to its stretchability.

- Recessed Lines:

- The recessed lines in rib knit fabric are formed by purl stitches. These stitches are pushed to the back of the fabric, creating a visually recessed area between the raised ribs.

- The combination of knit and purl stitches produces a balanced and flexible fabric.

- Vertical Alignment:

- The raised ribs and recessed lines align vertically, running parallel to each other along the length of the fabric.

- This vertical alignment contributes to the fabric’s stretch in the lengthwise direction.

- Symmetry:

- In many rib knit fabrics, the knit and purl stitches are arranged symmetrically. For example, in 1×1 rib, a knit stitch is followed by a purl stitch, and this sequence repeats across the fabric.

- Varied Rib Patterns:

- Different rib knit patterns can be created by varying the ratio of knit and purl stitches. Common patterns include 1×1 rib, 2×2 rib, and so on.

- The choice of rib pattern can influence the fabric’s appearance, texture, and stretch characteristics.

- Stretch and Recovery:

- The alternating structure of raised and recessed lines imparts excellent elasticity to rib knit fabric.

- The fabric can stretch easily in the width and length directions and then recover its original shape, making it suitable for garments that require flexibility.

Elasticity:

Rib knit fabrics are known for their excellent stretch and recovery. The alternating raised and lowered stitches create a natural elasticity, allowing the fabric to stretch horizontally.

- Horizontal Stretch:

- The alternating raised (knit) and lowered (purl) stitches in rib knit fabrics primarily contribute to their horizontal or widthwise stretch.

- This horizontal stretch allows the fabric to accommodate body movements and ensures a comfortable fit.

- Bias Stretch:

- In addition to horizontal stretch, rib knit fabrics may also exhibit some diagonal or bias stretch. This is because the raised and lowered stitches create a diagonal orientation along the fabric’s surface.

- The bias stretch enhances the overall flexibility of the fabric, making it suitable for garments that need to adapt to various body contours.

- Two-Way Stretch:

- Rib knit fabrics generally provide a two-way stretch, meaning they stretch both horizontally and vertically.

- This two-way stretch is beneficial for garments that require flexibility in multiple directions, enhancing comfort and ease of movement.

- Recovery:

- While rib knit fabrics stretch easily, they also have excellent recovery. After being stretched, the fabric tends to bounce back to its original shape.

- The recovery properties are crucial for maintaining the garment’s structure, especially in areas like cuffs and hems, where elasticity is essential.

- Rib Pattern Influence:

- The specific rib pattern used in the fabric, such as 1×1 rib or 2×2 rib, can influence the degree of stretch and recovery.

- For example, a 2×2 rib might provide a slightly firmer structure compared to a 1×1 rib due to the arrangement of stitches.

- Adaptability to Body Contours:

- The natural elasticity of rib knit fabrics allows them to adapt to different body contours without losing their shape.

- This adaptability makes rib knit suitable for various garments, including close-fitting items like leggings, sleeves, and socks.

- Use in Waistbands and Cuffs:

- Rib knit fabrics are commonly used in waistbands and cuffs of garments where elasticity is crucial for a snug fit.

- The fabric’s stretch ensures that these areas can comfortably accommodate different body sizes without sacrificing comfort.

Understanding the elasticity of rib knit fabrics is key to appreciating their versatility and suitability for a wide range of clothing applications.

Vertical Ribs:

The vertical ribs give the fabric a textured appearance and enhance its visual appeal. The ribs can vary in width, creating different aesthetic effects.

- Textured Appearance:

- The primary characteristic of rib knit fabrics is the presence of vertical ribs, which are created by the raised knit stitches.

- These vertical ribs give the fabric a textured appearance, adding depth and visual interest to the surface.

- Rib Width Variation:

- The width of the vertical ribs in rib knit fabrics can vary, and this variation contributes to different aesthetic effects.

- Narrow ribs, as seen in 1×1 rib knit, create a subtle and fine texture, while wider ribs, as in 2×2 rib knit or other variations, can produce a bolder and more pronounced pattern.

- Visual Contrast:

- The contrast between the raised ribs and the recessed lines (created by purl stitches) enhances the visual appeal of the fabric.

- This play of light and shadow on the surface of the fabric adds a dynamic quality to its appearance.

- Stripe-Like Effect:

- The vertical ribs in rib knit fabrics can create a stripe-like effect, especially when there’s a noticeable contrast in color between the ribs and the recessed areas.

- This stripe-like effect can be used creatively in design to achieve specific visual patterns.

- Ribbing Direction:

- The direction of the ribs is parallel to the length of the fabric. This vertical alignment emphasizes the fabric’s verticality and contributes to its overall drape and stretch characteristics.

- Pattern Variation:

- Designers can experiment with different rib patterns, altering the arrangement or width of the ribs to create unique textures and patterns.

- For example, alternating wide and narrow ribs or using asymmetrical ribbing patterns can result in distinct visual effects.

- Emphasis on Silhouette:

- Vertical ribs can also be strategically used to draw attention to the silhouette of a garment.

- For example, in garments like dresses or skirts, vertical ribs can create a lengthening effect, making the wearer appear taller.

- Textural Variety in Fashion:

- Rib knit fabrics with vertical ribs are commonly used in fashion to add textural variety to garments.

- They are popular for sweaters, cardigans, and other knitwear items where the textured surface enhances the overall aesthetic.

Versatility:

Rib knit is a versatile fabric that is commonly used for various clothing items, including sweaters, T-shirts, cuffs, collars, and other garments that require stretch and flexibility.

- Comfortable Fit:

- Rib knit fabric’s inherent stretch and flexibility contribute to a comfortable and accommodating fit.

- This quality makes it suitable for a wide range of garments, ensuring ease of movement and adaptability to different body shapes.

- Adaptability to Body Contours:

- The natural elasticity of rib knit allows it to conform to the body’s contours, making it an ideal choice for close-fitting garments.

- It provides a flattering silhouette without compromising on comfort.

- Cuffs and Collars:

- Rib knit is commonly used for cuffs and collars in various garments, such as sweaters, jackets, and sweatshirts.

- The fabric’s stretch ensures that cuffs stay in place and collars provide a snug fit without feeling restrictive.

- Sweaters and Knitwear:

- Rib knit is a popular choice for sweaters and other knitwear items. It adds texture and visual interest to the fabric while providing the necessary stretch for a cozy and comfortable fit.

- T-Shirts and Tops:

- T-shirts and tops made from rib knit fabric offer a combination of style and comfort.

- The stretchiness of the fabric allows for a form-fitting design without sacrificing ease of movement.

- Versatile Patterns:

- Rib knit comes in various patterns, such as 1×1 rib, 2×2 rib, and more. Each pattern offers a unique visual texture, allowing for versatility in design.

- Designers can choose specific rib patterns to achieve different looks and effects in their creations.

- Layering:

- Rib knit fabrics are excellent for layering due to their thin and lightweight nature. They can be comfortably worn under other garments without adding bulk.

- This makes rib knit suitable for year-round wear, as it can provide warmth in colder months and breathability in warmer seasons.

- Casual and Formal Wear:

- Rib knit fabrics can be used for both casual and formal wear, depending on the design and styling of the garment.

- From casual T-shirts to more sophisticated knit dresses, rib knit offers versatility in creating a range of fashion items.

- Accessories:

- In addition to clothing, rib knit is often used for accessories such as scarves, hats, and gloves.

- The stretch and flexibility of the fabric make it comfortable to wear in various accessory styles.

- Blend of Fibers:

- Rib knit fabrics can be made from a variety of fibers or blends, allowing for versatility in terms of texture, warmth, and care requirements.

- Cotton, wool, synthetic fibers, and blends offer different properties, making rib knit adaptable to diverse preferences and needs.

Cotton, Wool, or Synthetic Fibers:

Rib knit fabrics can be made from a variety of materials, including cotton, wool, synthetic fibers like polyester or nylon, or blends of these materials. The choice of fiber affects the fabric’s properties, such as breathability, warmth, and texture.

Comfort:

The stretch and flexibility of rib knit contribute to the comfort of garments made from this fabric. It allows for ease of movement and a snug fit.

- Cotton:

- Breathability: Cotton rib knit fabrics are known for their breathability. They allow air to circulate, making them comfortable in warmer weather.

- Softness: Cotton fibers have a natural softness, providing a pleasant feel against the skin.

- Absorbency: Cotton has good moisture absorption properties, making it suitable for activewear or garments worn in humid conditions.

- Wool:

- Insulation: Wool rib knit fabrics offer excellent insulation, providing warmth in colder weather. Wool fibers trap and retain heat, making them ideal for winter garments.

- Moisture Wicking: Wool has natural moisture-wicking properties, helping to keep the skin dry by drawing moisture away from the body.

- Natural Elasticity: Wool fibers have a degree of natural elasticity, enhancing the fabric’s stretch and recovery.

- Synthetic Fibers (e.g., Polyester, Nylon):

- Durability: Synthetic rib knit fabrics are often more durable and resistant to wear and tear compared to natural fibers.

- Wrinkle Resistance: Synthetic fibers are less prone to wrinkling, making garments made from these materials easier to care for.

- Quick Drying: Polyester and nylon are quick-drying fibers, making them suitable for activewear or garments exposed to moisture.

- Blends:

- Enhanced Properties: Blending different fibers combines the strengths of each material. For example, a cotton-wool blend may offer a balance between breathability and warmth.

- Reduced Shrinkage: Blends can reduce the shrinkage that may occur with pure cotton or wool, improving the fabric’s stability.

- Cost Efficiency: Blends can be more cost-effective while maintaining desirable properties of natural fibers.

- Texture and Feel:

- Cotton: Provides a smooth and soft texture.

- Wool: Adds a natural, slightly textured feel to the fabric.

- Synthetic Fibers: Can contribute to a sleek and smooth texture.

- Environmental Considerations:

- Cotton: Considered a natural and biodegradable fiber, but the production may involve pesticides and water-intensive cultivation.

- Wool: A natural, renewable resource, but the production process may involve grazing practices that impact the environment.

- Synthetic Fibers: Typically derived from petrochemicals, which raises environmental concerns, but advancements in sustainable alternatives are being explored.

- Application-Specific Considerations:

- Activewear: Polyester and nylon blends for moisture-wicking and quick-drying properties.

- Casual Wear: Cotton for comfort and breathability.

- Winter Garments: Wool for insulation and warmth.

Common Uses:

Rib knit is commonly used for creating cuffs and collars on garments, as well as for making sweaters, cardigans, and various types of activewear. It is also used in the production of accessories like scarves and hats. Let’s delve into more detail regarding the common uses of rib knit fabric in various garments and accessories:

- Cuffs and Collars:

- Purpose: Rib knit is frequently employed in the creation of cuffs and collars in garments such as sweaters, jackets, and sweatshirts.

- Function: The stretch and elasticity of rib knit ensure that cuffs stay in place and collars maintain a snug fit without being overly constrictive.

- Sweaters and Cardigans:

- Construction: Rib knit is a popular choice for the body and sleeves of sweaters and cardigans.

- Aesthetic Appeal: The textured appearance created by the vertical ribs adds visual interest to the fabric, enhancing the overall aesthetic of the garment.

- T-Shirts and Tops:

- Usage: Rib knit is often utilized in the production of T-shirts, tank tops, and other casual tops.

- Comfort: The fabric’s stretch and flexibility contribute to a comfortable fit, making it suitable for everyday wear.

- Activewear:

- Performance: Rib knit fabrics made from synthetic fibers like polyester or nylon are commonly found in activewear.

- Moisture Management: The quick-drying and moisture-wicking properties of synthetic rib knits make them suitable for sportswear, ensuring comfort during physical activities.

- Dresses and Skirts:

- Versatility: Rib knit’s stretchiness makes it adaptable to various garment styles, including dresses and skirts.

- Body-Hugging Styles: It is often chosen for body-hugging or form-fitting designs, providing a flattering silhouette.

- Accessories – Scarves and Hats:

- Texture: Rib knit adds texture to accessories like scarves and hats.

- Comfort: The stretch in rib knit allows scarves to drape nicely, and hats to provide a comfortable fit while maintaining shape.

- Leggings and Pants:

- Fit and Comfort: Rib knit is used in the creation of leggings and pants where stretch and flexibility are essential for a comfortable and form-fitting look.

- Waistbands: It is commonly used for waistbands to ensure a secure fit without compromising comfort.

- Children’s Wear:

- Practicality: The stretch and ease of movement provided by rib knit make it a practical choice for children’s clothing.

- Durability: It withstands the wear and tear associated with active play.

- Undergarments:

- Comfort: Rib knit fabrics, especially those made from soft and breathable materials, are used in the production of underwear and undershirts for their comfort and stretch.

- Layering Pieces:

- Thin and Lightweight: Rib knit fabrics are often thin and lightweight, making them suitable for layering without adding bulk.

Ribbing Patterns:

Different ribbing patterns exist, such as 1×1 rib, 2×2 rib, and 2×1 rib, indicating the arrangement of raised and lowered stitches. For example, in 1×1 rib, each column consists of one raised stitch followed by one recessed stitch. Let’s

delve into more detail about different ribbing patterns commonly used in rib knit fabrics:

- 1×1 Rib:

- Arrangement: In 1×1 rib, each column consists of one raised stitch (knit stitch) followed by one recessed stitch (purl stitch).

- Symmetry: The pattern is highly symmetrical, creating a balanced and uniform texture.

- Flexibility: This pattern provides a high degree of stretch and flexibility, making it commonly used for cuffs, collars, and hems.

- 2×2 Rib:

- Arrangement: In 2×2 rib, each column consists of two raised stitches (knit stitches) followed by two recessed stitches (purl stitches).

- Wider Ribs: The wider ribs in 2×2 rib create a bolder and more pronounced pattern compared to 1×1 rib.

- Structure: This pattern often results in a slightly firmer structure, making it suitable for various garment elements.

- 2×1 Rib:

- Arrangement: In 2×1 rib, each column consists of two raised stitches (knit stitches) followed by one recessed stitch (purl stitch).

- Asymmetry: This pattern introduces an element of asymmetry, creating an interesting visual effect.

- Versatility: 2×1 rib can offer a balance between the pronounced texture of 2×2 rib and the more subtle texture of 1×1 rib, providing versatility in design.

- 3×1 Rib and Beyond:

- Arrangement: Other variations, such as 3×1 rib, 4×2 rib, and beyond, involve different ratios of raised and lowered stitches.

- Visual Effects: Increasing the number of knit stitches before the purl stitches or varying the ratios can result in unique visual effects and textures.

- Design Freedom: These variations offer designers the freedom to create customized patterns based on their aesthetic preferences and intended garment style.

- Half Brioche Rib:

- Arrangement: In this pattern, each column consists of a combination of knit stitches and yarn overs.

- Texture: Half Brioche Rib creates a textured fabric with a unique, reversible appearance.

- Warmth: The texture adds warmth, making it suitable for colder weather garments.

- Cable Rib:

- Arrangement: Cable rib involves incorporating cable stitches into the ribbing pattern, creating a textured and visually appealing fabric.

- Complexity: Cable rib adds complexity to the pattern, offering a sophisticated and intricate look.

- Design Element: Often used in sweaters and other knitwear items as a decorative design element.

Drapability:

Depending on the fiber content, rib knit fabrics can vary in terms of drape. Lighter-weight rib knits may have a more fluid drape, while heavier versions may be more structured. Let’s

explore how the drape of rib knit fabrics is influenced by their fiber content and weight:

- Lightweight Rib Knits:

- Fiber Influence: Rib knit fabrics made from lightweight fibers like cotton or rayon tend to have a more fluid and drapey quality.

- Softness: These fabrics often have a softer and more supple feel, enhancing their ability to drape gracefully.

- Ideal for Draping Styles: Lightweight rib knits are suitable for garments and styles that require a gentle and flowing drape, such as flowing dresses, loose tops, and lightweight scarves.

- Medium-weight Rib Knits:

- Fiber Influence: Fabrics made from a blend of fibers, including cotton, polyester, or wool, in medium weights, offer a balance between structure and drape.

- Versatility: Medium-weight rib knits are versatile, providing a combination of structure and fluidity, making them suitable for various garment types.

- Common in Sweaters: They are often used in the construction of sweaters and cardigans, providing enough weight for warmth while maintaining a degree of drape.

- Heavyweight Rib Knits:

- Fiber Influence: Fabrics made from heavier fibers such as wool or blends with a higher wool content tend to have a more structured drape.

- Thickness and Weight: The thickness and weight of the fabric contribute to a more substantial and structured appearance.

- Ideal for Outerwear: Heavyweight rib knits are commonly used in the production of outerwear like jackets and coats, where a more structured drape is desired for added warmth and support.

- Blended Fibers:

- Influence on Drape: Blending different fibers in rib knit fabrics allows for the customization of drape characteristics.

- Balancing Properties: Combining fibers with different inherent properties can result in a fabric that balances drape, structure, and other desirable characteristics.

- Durability: Blends may also enhance the durability and longevity of the fabric.

- Stretch and Drape Relationship:

- Elasticity Influence: The inherent stretchiness of rib knit fabrics can also influence their drape.

- Conforming to Body: The stretch allows the fabric to conform to the body’s contours, contributing to a flattering drape.

- Enhanced Comfort: The combination of stretch and drape enhances the overall comfort and wearability of garments made from rib knit.

- Drape in Design:

- Design Considerations: Designers often consider the intended drape of the fabric when selecting rib knit for specific garments.

- Aesthetic Choices: The choice between a fluid drape or a more structured drape is often a design decision that complements the overall aesthetic of the garment.

Warmth:

Rib knit fabrics made from wool or other insulating fibers provide warmth, making them suitable for colder weather garments. Let’s move into more detail regarding how the warmth of rib knit fabrics is influenced by the choice of fibers, particularly those with insulating properties like wool:

- Wool Content:

- Insulating Properties: Wool is known for its excellent insulating properties, providing natural warmth.

- Air Trapping: Wool fibers trap and retain air within their structure, creating a layer of insulation that helps regulate body temperature.

- Cold-Weather Suitability: Rib knit fabrics with a higher wool content are well-suited for colder weather garments, offering warmth without excessive bulk.

- Natural Thermal Regulation:

- Breathability: Wool has inherent breathability, allowing moisture to evaporate and preventing overheating.

- Regulation of Temperature: This natural thermal regulation makes woolen rib knit garments comfortable in a range of temperatures, keeping the wearer warm in cool conditions while avoiding excessive heat retention.

- Layering for Added Warmth:

- Suitable for Layering: Rib knit fabrics with wool are suitable for layering, as they provide warmth without contributing excessive thickness.

- Base Layer Options: They are often used as base layers for additional insulation in cold climates.

- Blend of Fibers:

- Balancing Warmth and Other Qualities: Rib knit fabrics made from a blend of fibers, including wool and other materials, allow for a balance between warmth, comfort, and other desirable properties.

- Durability: Blends may enhance the durability and wear resistance of the fabric, extending its usability over time.

- Layering in Winter Wear:

- Sweaters and Cardigans: Rib knit fabrics with wool content are commonly used in the production of sweaters and cardigans, offering warmth and comfort during colder seasons.

- Winter Accessories: Scarves, hats, and gloves made from rib knit fabrics with wool provide additional warmth and insulation.

- Insulating Air Pockets:

- Vertical Ribs’ Role: The vertical ribs in rib knit fabrics contribute to the creation of insulating air pockets within the fabric structure.

- Enhanced Thermal Efficiency: This helps enhance the fabric’s thermal efficiency by trapping and maintaining warmth close to the body.

- Wool Blends for Versatility:

- Blend with Other Fibers: Wool blends, combining wool with synthetic fibers or other natural fibers, offer versatility in terms of warmth, moisture management, and ease of care.

- Adaptable to Different Climates: These blends can make rib knit garments adaptable to a variety of climates, offering warmth without sacrificing other desirable qualities.

Washability:

The washability of rib knit fabrics depends on the fiber content. Some rib knits made from natural fibers like cotton may be machine washable, while others, especially those with wool content, may require more delicate care.

Rib knit is a popular choice in the textile industry for its combination of stretch, comfort, and textured appearance. The versatility of this fabric makes it suitable for a wide range of apparel applications. Here are more details regarding the washability of rib knit fabrics based on their fiber content:

- Cotton Rib Knits:

- Machine Washable: Rib knit fabrics made from cotton are often machine washable, making them easy to care for.

- Durable: Cotton is a durable natural fiber that can withstand regular washing.

- Shrinkage: While cotton may experience some initial shrinkage, pre-shrunk or blended varieties are available to minimize this effect.

- Synthetic Fiber Rib Knits (Polyester, Nylon):

- Machine Washable: Rib knit fabrics made from synthetic fibers like polyester and nylon are typically machine washable.

- Quick Drying: These fibers are known for their quick-drying properties, making garments easy to care for.

- Resistant to Wrinkling: Synthetic fibers are less prone to wrinkling, contributing to low-maintenance care.

- Wool or Wool Blend Rib Knits:

- Delicate Care: Rib knit fabrics with wool content usually require more delicate care.

- Hand Wash or Gentle Cycle: Hand washing in cold water or using the gentle cycle on a washing machine is often recommended.

- Avoid Agitation: Aggressive washing can lead to felting or distortion of the fabric, so it’s essential to handle wool garments with care.

- Laying Flat to Dry: Wool or wool blend rib knit items are typically laid flat to dry to maintain their shape.

- Blended Rib Knits:

- Balanced Care: Rib knit fabrics made from blends of fibers often strike a balance between the care requirements of different materials.

- Follow Care Instructions: It’s important to follow the care instructions provided by the manufacturer to ensure the longevity of the garment.

- Wool-Cotton Blend Example: A rib knit garment with a blend of wool and cotton might require a careful balance in washing, taking into account the needs of both fibers.

- Pre-Treated Fabrics:

- Pre-Shrunk Varieties: Some rib knit fabrics, regardless of fiber content, may be pre-treated or pre-shrunk during manufacturing to minimize shrinkage after washing.

- Stability: Pre-treatment enhances the stability of the fabric and ensures that it maintains its shape through wash and wear.

- Colorfastness:

- Consideration for Dyes: It’s important to consider the colorfastness of the fabric, especially in colored or printed rib knit garments.

- Follow Care Labels: Following care labels is crucial to preserving the color vibrancy and preventing bleeding or fading during washing.

- Handwashing vs. Machine Washing:

- Delicate Fabrics: Regardless of the fiber content, delicate rib knit fabrics may benefit from handwashing to prevent abrasion or distortion.

- Machine Washable Varieties: For machine washable rib knit fabrics, using a gentle cycle and a mild detergent is recommended.